When a conveyor is partly mounted in a machine, it may be a problem to fit the the drive unit. One solution is to use an intermediate drive, another solution is a reversed conveyor with a guided chain drive unit. A reversed conveyor can be created in FlexLink Design Tool by adjusting the drive unit component properties.

Component properties adjustments

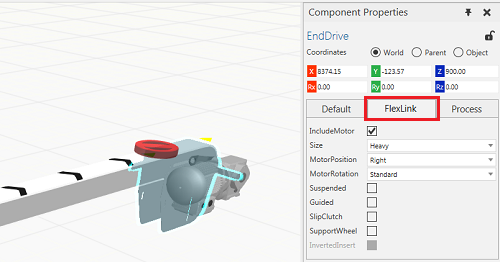

Select the Drive unit component.

Select the FlexLink tab in the Component Properties panel.

Select the Guided parameter check box.

Note: Do not change InvertedInsert parameter check box. InvertedInsert is only used for "building help" in some very special cases. Not for product flow direction.

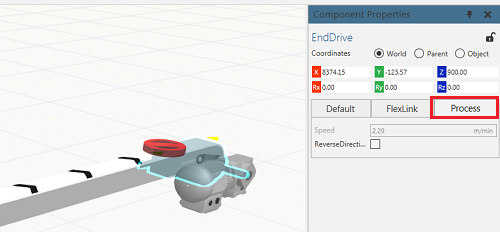

Select the Process tab in the Components Properties panel.

Select the ReversedDirection parameter check box.

The product flow direction arrows on the chain are changed to show the reversed direction. However, these arrows can be hard to see when the conveyor is not completed or if warnings exist in the Message window. To display the arrows use View tab/3D group/Visualize conveyors check box to switch on/off.

Reversed direction also works with the simulation components. If a Feeder component is added to the drive unit end of the conveyor, the products will flow towards the idler end unit.

Warning messages

Several types of warning messages may appear in the Message Window when reversed direction is used:

The conveyor should contain a chain installation section

Solution: Add a chain installation component.

End drive component has not yet been configured

Solution: After adjusting the parameters a proper configuration is necessary. Click Home tab/Component group/Configure button to configure the component. Or use the keyboard shortcut CTRL + SHIFT + C.

Conveyor with reversed direction should not be longer than 3000 mm

Solution: Consider a design change.