Background

The Parameter Setting Tool contains a wizard for setting the parameters in the function or drive units. This is started with the Change Node or the New Node command, from the Edit menu. When all questions in the wizard are answered the software send down the corresponding parameter settings to the unit. To see exactly which parameter set it is the Advance mode is used, from the Tools menu. Interlock is not affecting by the different variants and is excluded from this article. The Function group and Function variant are underlying variant parameters controlling all other variant parameters. The Function group is decided when the user chooses the type of the unit. The Function variant is a sub group based on the exact control type. After the unit is updated with the wizard the settings can be fine tuned from the Parameter Setting Tool. These can also be read or written from a line controller if CANopen, DeviceNet, Ethernet/IP or Profinet is chosen. All possible options in the wizard are described in different chapters below.

User Defined

- Function group: 0

- Function variant: 0

- A-Bus protocol: Optional

- Enable-Reset: Optional

- Control: Optional

- Variant: Optional

This variant could be used for setting the Function group and function variant to a value not connected to any specific functionality. The user could set the Function Parameter 1-4 to any value. It is possible to set this variant in the Wizard or from the Advanced mode. The Function Parameters has to be set in Advanced mode.

Drive motor, Right

- Function group: 1

- Function variant: 1

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Line control

- Variant: No Choice

Motor starts when enable bit is sent via CANopen. Alarm resets on reset bit via CANopen. Speed setpoint can be sent via CANopen (Line controller) or PST.

- Function variant: 2

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Line control

- Variant: No Choice

Motor starts when enable bit is sent via DeviceNet. Alarm resets on reset bit via DeviceNet. Speed setpoint can be sent via DeviceNet (Line controller) or PST.

- Function variant: 3

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: Sensor

Motor starts when power is on. Alarm resets when reboot. Sensor DI1 is increasing speed setpoint. Sensor DI2 is decreasing speed setpoint. When sensor DI3 is active Speed setpoint 2 is activated. When Speed setpoint 2 is activated DI1 and DI2 are tuning speed setpoint 2.

- Function variant: 145

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: Limit switch

Motor starts when power is on. Alarm resets when reboot. The conveyor is running with speed setpoint 1 until Sensor DI3 is triggered. Then it stops for the limit switch wait delay before it starts with speed setpoint 2 (should be set to reverse direction). Then it stops by DI4 when it waits and starts over with setpoint 1 again. Sensor DI1 is increasing the currently activated speed setpoint. Sensor DI2 is decreasing the currently activated speed setpoint.

- Function variant: 289

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: Sensor OS

Motor starts when power is on. Alarm resets when reboot. When sensor DI4 is active motor stops after interlock on delay. When sensor DI3 is active instead motor starts after interlock off delay. The conveyor is running with speed setpoint 1.

- Function variant: 171

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: No Choice

Motor starts when enable bit is sent via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Speed setpoint can be sent via Ethernet/IP (Line controller) or PST.

- Function variant: 172

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: No Choice

Motor starts when enable bit is sent via Profinet. Alarm resets on reset bit via Profinet. Speed setpoint can be sent via Profinet (Line controller) or PST.

Drive motor, Left

- Function group: 2

- Function variant: 4

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Line control

- Variant: No Choice

Motor starts when enable bit is sent via CANopen. Alarm resets on reset bit via CANopen. Speed setpoint can be sent via CANopen (Line controller) or PST.

- Function variant: 5

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Line control

- Variant: No Choice

Motor starts when enable bit is sent via DeviceNet. Alarm resets on reset bit via DeviceNet. Speed setpoint can be sent via DeviceNet (Line controller) or PST.

- Function variant: 6

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: Sensor

Motor starts when power is on. Alarm resets when reboot. Sensor DI1 is increasing speed setpoint. Sensor DI2 is decreasing speed setpoint. When sensor DI3 is active Speed setpoint 2 is activated. When Speed setpoint 2 is activated DI1 and DI2 are tuning speed setpoint 2.

- Function variant: 146

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: Limit switch

Motor starts when power is on. Alarm resets when reboot. The conveyor is running with speed setpoint 1 until Sensor DI3 is triggered. Then it stops for the limit switch wait delay before it starts with speed setpoint 2 (should be set to reverse direction). Then it stops by DI4 when it waits and starts over with setpoint 1 again. Sensor DI1 is increasing the currently activated speed setpoint. Sensor DI2 is decreasing the currently activated speed setpoint.

- Function variant: 290

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: Sensor OS

Motor starts when power is on. Alarm resets when reboot. When sensor DI4 is active motor stops after interlock on delay. When sensor DI3 is active instead motor starts after interlock off delay. The conveyor is running with speed setpoint 1.

- Function variant: 173

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: No Choice

Motor starts when enable bit is sent via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Speed setpoint can be sent via Ethernet/IP (Line controller) or PST.

- Function variant: 174

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: No Choice

Motor starts when enable bit is sent via Profinet. Alarm resets on reset bit via Profinet. Speed setpoint can be sent via Profinet (Line controller) or PST.

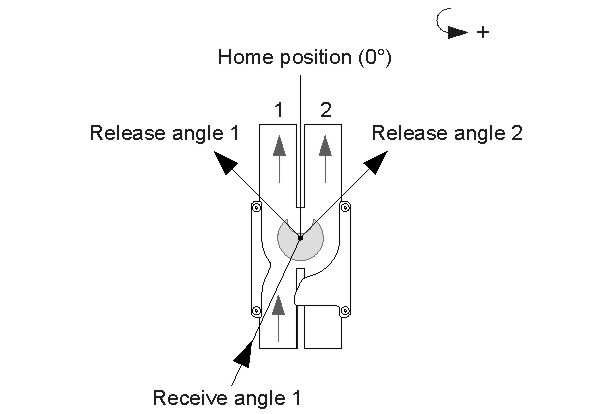

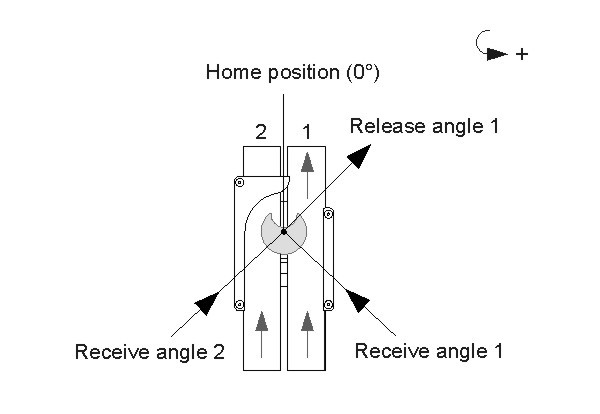

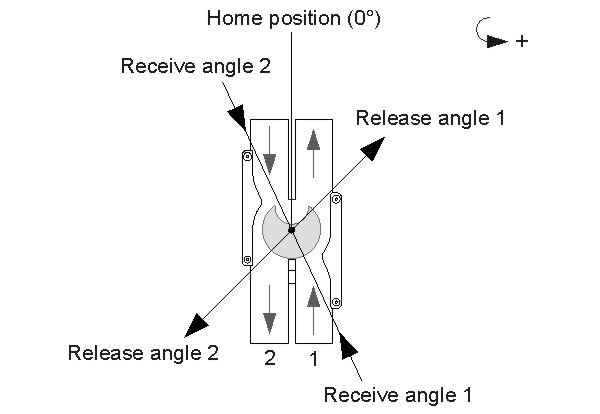

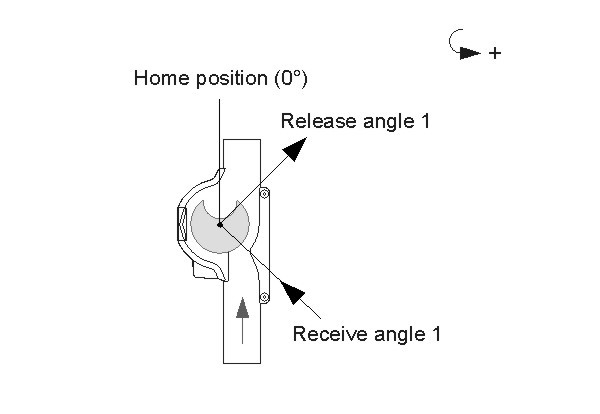

Diverter parallel, Right

- Function group: 3

- Function variant: 7

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Autonomous

- Variant: 1/1

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Diverts one puck to conveyor 1 and then one to conveyor 2.

- Function variant: 8

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Sensor

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Diverts to conveyor 1 if DI2 is activated or to conveyor 2 if DI2 is not activated.

- Function variant: 9

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Inverted sensor

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Diverts to conveyor 1 if DI2 is not activated or to conveyor 2 if DI2 activated.

- Function variant: 10

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Guide disc moves to wait position (closed). Waiting for PLC command:

- Receive from conveyor 1 and (Release to conveyor 2 or Release to conveyor 1)

This variant is recommended for RFID functions

- Function variant: 11

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally open

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Guide disc waits at Receive angle 1. Waiting for PLC command:

- Release to conveyor 1 or Release to conveyor 2

- Function variant: 12

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: 1/1

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Diverts one puck to conveyor 1 and then one to conveyor 2.

- Function variant: 13

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Sensor

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Diverts to conveyor 1 if DI2 is activated or to conveyor 2 if DI2 is not activated.

- Function variant: 14

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Inverted sensor

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Diverts to conveyor 1 if DI2 is not activated or to conveyor 2 if DI2 activated.

- Function variant: 15

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Guide disc moves to wait position (closed). Waiting for PLC command:

- Receive from conveyor 1 and (Release to conveyor 2 or Release to conveyor 1)

This variant is recommended for RFID functions

- Function variant: 16

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally open

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Guide disc waits at Receive angle 1. Waiting for PLC command:

- Release to conveyor 1 or Release to conveyor 2

- Function variant: 17

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: 1/1

Motor is enabled when power is on. Alarm resets when reboot. Diverts one puck to conveyor 1 and then one to conveyor 2.

- Function variant: 18

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: Sensor

Motor is enabled when power is on. Alarm resets when reboot. Diverts to conveyor 1 if DI2 is activated or to conveyor 2 if DI2 is not activated.

- Function variant: 19

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: Inverted sensor

Motor is enabled when power is on. Alarm resets when reboot. Diverts to conveyor 1 if DI2 is not activated or to conveyor 2 if DI2 activated.

- Function variant: 175

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Autonomous

- Variant: 1/1

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Diverts one puck to conveyor 1 and then one to conveyor 2.

- Function variant: 176

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Sensor

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Diverts to conveyor 1 if DI2 is activated or to conveyor 2 if DI2 is not activated.

- Function variant: 177

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Inverted sensor

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Diverts to conveyor 1 if DI2 is not activated or to conveyor 2 if DI2 activated.

- Function variant: 178

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Guide disc moves to wait position (closed). Waiting for PLC command:

- Receive from conveyor 1 and (Release to conveyor 2 or Release to conveyor 1)

This variant is recommended for RFID functions

- Function variant: 179

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally open

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Guide disc waits at Receive angle 1. Waiting for PLC command:

- Release to conveyor 1 or Release to conveyor 2

- Function variant: 180

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: 1/1

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Diverts one puck to conveyor 1 and then one to conveyor 2.

- Function variant: 181

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Sensor

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Diverts to conveyor 1 if DI2 is activated or to conveyor 2 if DI2 is not activated.

- Function variant: 182

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Inverted sensor

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Diverts to conveyor 1 if DI2 is not activated or to conveyor 2 if DI2 activated.

- Function variant: 183

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Guide disc moves to wait position (closed). Waiting for PLC command:

- Receive from conveyor 1 and (Release to conveyor 2 or Release to conveyor 1)

This variant is recommended for RFID functions

- Function variant: 184

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally open

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Guide disc waits at Receive angle 1. Waiting for PLC command:

- Release to conveyor 1 or Release to conveyor 2

- Function variant: 294

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed, only PLC

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Guide disc moves to wait position (closed). Waiting for PLC command:

- Receive from conveyor 1 and (Release to conveyor 2 or Release to conveyor 1)

This variant is recommended for RFID functions

- Function variant: 295

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally open, only PLC

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Guide disc waits at Receive angle 1. Waiting for PLC command:

- Release to conveyor 1 or Release to conveyor 2

- Function variant: 296

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed, only PLC

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Guide disc moves to wait position (closed). Waiting for PLC command:

- Receive from conveyor 1 and (Release to conveyor 2 or Release to conveyor 1)

This variant is recommended for RFID functions

- Function variant: 297

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally open, only PLC

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Guide disc waits at Receive angle 1. Waiting for PLC command:

- Release to conveyor 1 or Release to conveyor 2

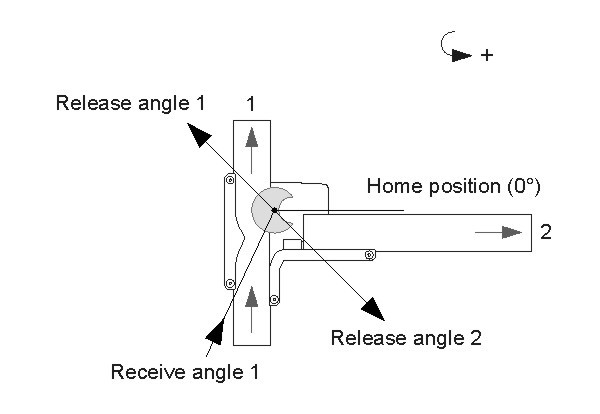

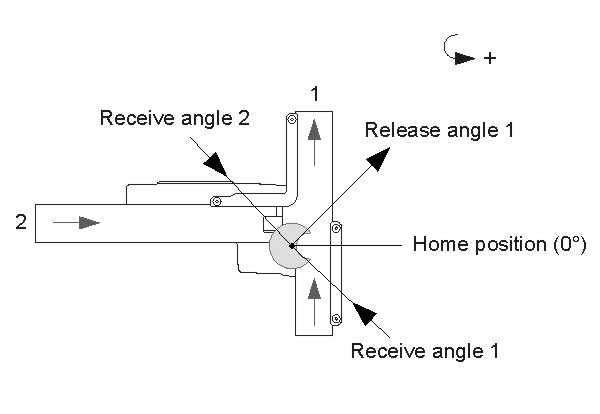

Diverter 90, Right

- Function group: 4

- Function variant: 20

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Autonomous

- Variant: 1/1

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Diverts one puck to conveyor 1 and then one to conveyor 2.

- Function variant: 21

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Sensor

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Diverts to conveyor 1 if DI2 is activated or to conveyor 2 if DI2 is not activated.

- Function variant: 22

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Inverted sensor

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Diverts to conveyor 1 if DI2 is not activated or to conveyor 2 if DI2 activated.

- Function variant: 23

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Guide disc moves to wait position (closed). Waiting for PLC command:

- Receive from conveyor 1 and (Release to conveyor 2 or Release to conveyor 1)

This variant is recommended for RFID functions

- Function variant: 24

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally open

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Guide disc waits at Receive angle 1. Waiting for PLC command:

- Release to conveyor 1 or Release to conveyor 2

- Function variant: 25

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: 1/1

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Diverts one puck to conveyor 1 and then one to conveyor 2.

- Function variant: 26

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Sensor

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Diverts to conveyor 1 if DI2 is activated or to conveyor 2 if DI2 is not activated.

- Function variant: 27

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Inverted sensor

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Diverts to conveyor 1 if DI2 is not activated or to conveyor 2 if DI2 activated.

- Function variant: 28

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Guide disc moves to wait position (closed). Waiting for PLC command:

- Receive from conveyor 1 and (Release to conveyor 2 or Release to conveyor 1)

This variant is recommended for RFID functions

- Function variant: 29

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally open

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Guide disc waits at Receive angle 1. Waiting for PLC command:

- Release to conveyor 1 or Release to conveyor 2

- Function variant: 30

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: 1/1

Motor is enabled when power is on. Alarm resets when reboot. Diverts one puck to conveyor 1 and then one to conveyor 2.

- Function variant: 31

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: Sensor

Motor is enabled when power is on. Alarm resets when reboot. Diverts to conveyor 1 if DI2 is activated or to conveyor 2 if DI2 is not activated.

- Function variant: 32

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: Inverted sensor

Motor is enabled when power is on. Alarm resets when reboot. Diverts to conveyor 1 if DI2 is not activated or to conveyor 2 if DI2 activated.

- Function variant: 185

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Autonomous

- Variant: 1/1

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Diverts one puck to conveyor 1 and then one to conveyor 2.

- Function variant: 186

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Sensor

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Diverts to conveyor 1 if DI2 is activated or to conveyor 2 if DI2 is not activated.

- Function variant: 187

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Inverted sensor

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Diverts to conveyor 1 if DI2 is not activated or to conveyor 2 if DI2 activated.

- Function variant: 188

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Guide disc moves to wait position (closed). Waiting for PLC command:

- Receive from conveyor 1 and (Release to conveyor 2 or Release to conveyor 1)

This variant is recommended for RFID functions

- Function variant: 189

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally open

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Guide disc waits at Receive angle 1. Waiting for PLC command:

- Release to conveyor 1 or Release to conveyor 2

- Function variant: 190

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: 1/1

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Diverts one puck to conveyor 1 and then one to conveyor 2.

- Function variant: 191

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Sensor

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Diverts to conveyor 1 if DI2 is activated or to conveyor 2 if DI2 is not activated.

- Function variant: 192

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Inverted sensor

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Diverts to conveyor 1 if DI2 is not activated or to conveyor 2 if DI2 activated.

- Function variant: 193

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Guide disc moves to wait position (closed). Waiting for PLC command:

- Receive from conveyor 1 and (Release to conveyor 2 or Release to conveyor 1)

This variant is recommended for RFID functions

- Function variant: 194

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally open

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Guide disc waits at Receive angle 1. Waiting for PLC command:

- Release to conveyor 1 or Release to conveyor 2

- Function variant: 298

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed, only PLC

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Guide disc moves to wait position (closed). Waiting for PLC command:

- Receive from conveyor 1 and (Release to conveyor 2 or Release to conveyor 1)

This variant is recommended for RFID functions

- Function variant: 299

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally open, only PLC

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Guide disc waits at Receive angle 1. Waiting for PLC command:

- Release to conveyor 1 or Release to conveyor 2

- Function variant: 300

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed, only PLC

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Guide disc moves to wait position (closed). Waiting for PLC command:

- Receive from conveyor 1 and (Release to conveyor 2 or Release to conveyor 1)

This variant is recommended for RFID functions

- Function variant: 301

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally open, only PLC

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Guide disc waits at Receive angle 1. Waiting for PLC command:

- Release to conveyor 1 or Release to conveyor 2

Diverter Parallel, Left

- Function group: 5

- Function variant: 33

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Autonomous

- Variant: 1/1

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Diverts one puck to conveyor 1 and then one to conveyor 2.

- Function variant: 34

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Sensor

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Diverts to conveyor 1 if DI2 is activated or to conveyor 2 if DI2 is not activated.

- Function variant: 35

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Inverted sensor

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Diverts to conveyor 1 if DI2 is not activated or to conveyor 2 if DI2 activated.

- Function variant: 36

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Guide disc moves to wait position (closed). Waiting for PLC command:

- Receive from conveyor 1 and (Release to conveyor 2 or Release to conveyor 1)

This variant is recommended for RFID functions

- Function variant: 37

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally open

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Guide disc waits at Receive angle 1. Waiting for PLC command:

- Release to conveyor 1 or Release to conveyor 2

- Function variant: 38

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: 1/1

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Diverts one puck to conveyor 1 and then one to conveyor 2.

- Function variant: 39

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Sensor

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Diverts to conveyor 1 if DI2 is activated or to conveyor 2 if DI2 is not activated.

- Function variant: 40

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Inverted sensor

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Diverts to conveyor 1 if DI2 is not activated or to conveyor 2 if DI2 activated.

- Function variant: 41

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Guide disc moves to wait position (closed). Waiting for PLC command:

- Receive from conveyor 1 and (Release to conveyor 2 or Release to conveyor 1)

This variant is recommended for RFID functions

- Function variant: 42

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally open

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Guide disc waits at Receive angle 1. Waiting for PLC command:

- Release to conveyor 1 or Release to conveyor 2

- Function variant: 43

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: 1/1

Motor is enabled when power is on. Alarm resets when reboot. Diverts one puck to conveyor 1 and then one to conveyor 2.

- Function variant: 44

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: Sensor

Motor is enabled when power is on. Alarm resets when reboot. Diverts to conveyor 1 if DI2 is activated or to conveyor 2 if DI2 is not activated.

- Function variant: 45

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: Inverted sensor

Motor is enabled when power is on. Alarm resets when reboot. Diverts to conveyor 1 if DI2 is not activated or to conveyor 2 if DI2 activated.

- Function variant: 195

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Autonomous

- Variant: 1/1

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Diverts one puck to conveyor 1 and then one to conveyor 2.

- Function variant: 196

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Sensor

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Diverts to conveyor 1 if DI2 is activated or to conveyor 2 if DI2 is not activated.

- Function variant: 197

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Inverted sensor

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Diverts to conveyor 1 if DI2 is not activated or to conveyor 2 if DI2 activated.

- Function variant: 198

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Guide disc moves to wait position (closed). Waiting for PLC command:

- Receive from conveyor 1 and (Release to conveyor 2 or Release to conveyor 1)

This variant is recommended for RFID functions

- Function variant: 199

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally open

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Guide disc waits at Receive angle 1. Waiting for PLC command:

- Release to conveyor 1 or Release to conveyor 2

- Function variant: 200

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: 1/1

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Diverts one puck to conveyor 1 and then one to conveyor 2.

- Function variant: 201

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Sensor

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Diverts to conveyor 1 if DI2 is activated or to conveyor 2 if DI2 is not activated.

- Function variant: 202

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Inverted sensor

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Diverts to conveyor 1 if DI2 is not activated or to conveyor 2 if DI2 activated.

- Function variant: 203

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Guide disc moves to wait position (closed). Waiting for PLC command:

- Receive from conveyor 1 and (Release to conveyor 2 or Release to conveyor 1)

This variant is recommended for RFID functions

- Function variant: 204

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally open

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Guide disc waits at Receive angle 1. Waiting for PLC command:

- Release to conveyor 1 or Release to conveyor 2

- Function variant: 302

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed, only PLC

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Guide disc moves to wait position (closed). Waiting for PLC command:

- Receive from conveyor 1 and (Release to conveyor 2 or Release to conveyor 1)

This variant is recommended for RFID functions

- Function variant: 303

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally open, only PLC

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Guide disc waits at Receive angle 1. Waiting for PLC command:

- Release to conveyor 1 or Release to conveyor 2

- Function variant: 304

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed, only PLC

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Guide disc moves to wait position (closed). Waiting for PLC command:

- Receive from conveyor 1 and (Release to conveyor 2 or Release to conveyor 1)

This variant is recommended for RFID functions

- Function variant: 305

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally open, PLC only

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Guide disc waits at Receive angle 1. Waiting for PLC command:

- Release to conveyor 1 or Release to conveyor 2

Diverter 90, Left

- Function group: 6

- Function variant: 46

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Autonomous

- Variant: 1/1

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Diverts one puck to conveyor 1 and then one to conveyor 2.

- Function variant: 47

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Sensor

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Diverts to conveyor 1 if DI2 is activated or to conveyor 2 if DI2 is not activated.

- Function variant: 48

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Inverted sensor

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Diverts to conveyor 1 if DI2 is not activated or to conveyor 2 if DI2 activated.

- Function variant: 49

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Guide disc moves to wait position (closed). Waiting for PLC command:

- Receive from conveyor 1 and (Release to conveyor 2 or Release to conveyor 1)

This variant is recommended for RFID functions

- Function variant: 50

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally open

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Guide disc waits at Receive angle 1. Waiting for PLC command:

- Release to conveyor 1 or Release to conveyor 2

- Function variant: 51

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: 1/1

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Diverts one puck to conveyor 1 and then one to conveyor 2.

- Function variant: 52

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Sensor

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Diverts to conveyor 1 if DI2 is activated or to conveyor 2 if DI2 is not activated.

- Function variant: 53

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Inverted sensor

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Diverts to conveyor 1 if DI2 is not activated or to conveyor 2 if DI2 activated.

- Function variant: 54

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Guide disc moves to wait position (closed). Waiting for PLC command:

- Receive from conveyor 1 and (Release to conveyor 2 or Release to conveyor 1)

This variant is recommended for RFID functions

- Function variant: 55

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally open

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Guide disc waits at Receive angle 1. Waiting for PLC command:

- Release to conveyor 1 or Release to conveyor 2

- Function variant: 56

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: 1/1

Motor is enabled when power is on. Alarm resets when reboot. Diverts one puck to conveyor 1 and then one to conveyor 2.

- Function variant: 57

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: Sensor

Motor is enabled when power is on. Alarm resets when reboot. Diverts to conveyor 1 if DI2 is activated or to conveyor 2 if DI2 is not activated.

- Function variant: 58

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: Inverted sensor

Motor is enabled when power is on. Alarm resets when reboot. Diverts to conveyor 1 if DI2 is not activated or to conveyor 2 if DI2 activated.

- Function variant: 205

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Autonomous

- Variant: 1/1

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Diverts one puck to conveyor 1 and then one to conveyor 2.

- Function variant: 206

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Sensor

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Diverts to conveyor 1 if DI2 is activated or to conveyor 2 if DI2 is not activated.

- Function variant: 207

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Inverted sensor

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Diverts to conveyor 1 if DI2 is not activated or to conveyor 2 if DI2 activated.

- Function variant: 208

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Guide disc moves to wait position (closed). Waiting for PLC command:

- Receive from conveyor 1 and (Release to conveyor 2 or Release to conveyor 1)

This variant is recommended for RFID functions

- Function variant: 209

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally open

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Guide disc waits at Receive angle 1. Waiting for PLC command:

- Release to conveyor 1 or Release to conveyor 2

- Function variant: 210

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: 1/1

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Diverts one puck to conveyor 1 and then one to conveyor 2.

- Function variant: 211

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Sensor

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Diverts to conveyor 1 if DI2 is activated or to conveyor 2 if DI2 is not activated.

- Function variant: 212

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Autonomous

- Variant: Inverted sensor

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Diverts to conveyor 1 if DI2 is not activated or to conveyor 2 if DI2 activated.

- Function variant: 213

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Guide disc moves to wait position (closed). Waiting for PLC command:

- Receive from conveyor 1 and (Release to conveyor 2 or Release to conveyor 1)

This variant is recommended for RFID functions

- Function variant: 214

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally open

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Guide disc waits at Receive angle 1. Waiting for PLC command:

- Release to conveyor 1 or Release to conveyor 2

- Function variant: 306

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed, only PLC

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Guide disc moves to wait position (closed). Waiting for PLC command:

- Receive from conveyor 1 and (Release to conveyor 2 or Release to conveyor 1)

This variant is recommended for RFID functions

- Function variant: 307

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally open, only PLC

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Guide disc waits at Receive angle 1. Waiting for PLC command:

- Release to conveyor 1 or Release to conveyor 2

- Function variant: 360

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed, only PLC

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Guide disc moves to wait position (closed). Waiting for PLC command:

- Receive from conveyor 1 and (Release to conveyor 2 or Release to conveyor 1)

This variant is recommended for RFID functions

- Function variant: 361

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally open, only PLC

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Guide disc waits at Receive angle 1. Waiting for PLC command:

- Release to conveyor 1 or Release to conveyor 2

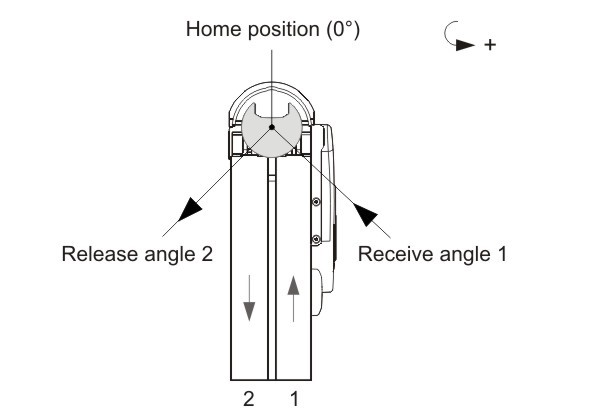

Merger parallel, Right

- Function group: 7

- Function variant: 59

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Autonomous

- Variant: No choice

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. First In First Out, FIFO

- Function variant: 60

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Line control

- Variant: No choice

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Waiting for PLC command:

- Receive from conveyor 1 or Receive from conveyor 2

- Function variant: 61

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: No choice

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. First In First Out, FIFO

- Function variant: 62

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Line control

- Variant: No choice

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Waiting for PLC command:

- Receive from conveyor 1 or Receive from conveyor 2

- Function variant: 63

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: No choice

Motor is enabled when power is on. Alarm resets when reboot. First In First Out, FIFO

- Function variant: 215

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Autonomous

- Variant: No choice

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. First In First Out, FIFO

- Function variant: 216

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Sensor

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Waiting for PLC command:

- Receive from conveyor 1 or Receive from conveyor 2

- Function variant: 217

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: No choice

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. First In First Out, FIFO

- Function variant: 218

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Sensor

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Waiting for PLC command:

- Receive from conveyor 1 or Receive from conveyor 2

- Function variant: 308

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Only PLC

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Waiting for PLC command:

- Receive from conveyor 1 or Receive from conveyor 2

- Function variant: 309

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Only PLC

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Waiting for PLC command:

- Receive from conveyor 1 or Receive from conveyor 2

Merger 90, Right

- Function group: 8

- Function variant: 64

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Autonomous

- Variant: No choice

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. First In First Out, FIFO

- Function variant: 65

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Line control

- Variant: No choice

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Waiting for PLC command:

- Receive from conveyor 1 or Receive from conveyor 2

- Function variant: 66

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: No choice

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. First In First Out, FIFO

- Function variant: 67

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Line control

- Variant: No choice

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Waiting for PLC command:

- Receive from conveyor 1 or Receive from conveyor 2

- Function variant: 68

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: No choice

Motor is enabled when power is on. Alarm resets when reboot. First In First Out, FIFO

- Function variant: 219

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Autonomous

- Variant: No choice

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. First In First Out, FIFO

- Function variant: 220

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Sensor

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Waiting for PLC command:

- Receive from conveyor 1 or Receive from conveyor 2

- Function variant: 221

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: No choice

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. First In First Out, FIFO

- Function variant: 222

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Sensor

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Waiting for PLC command:

- Receive from conveyor 1 or Receive from conveyor 2

- Function variant: 310

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Only PLC

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Waiting for PLC command:

- Receive from conveyor 1 or Receive from conveyor 2

- Function variant: 311

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Only PLC

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Waiting for PLC command:

- Receive from conveyor 1 or Receive from conveyor 2

Merger parallel, Left

- Function group: 9

- Function variant: 69

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Autonomous

- Variant: No choice

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. First In First Out, FIFO

- Function variant: 70

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Line control

- Variant: No choice

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Waiting for PLC command:

- Receive from conveyor 1 or Receive from conveyor 2

- Function variant: 71

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: No choice

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. First In First Out, FIFO

- Function variant: 72

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Line control

- Variant: No choice

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Waiting for PLC command:

- Receive from conveyor 1 or Receive from conveyor 2

- Function variant: 73

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: No choice

Motor is enabled when power is on. Alarm resets when reboot. First In First Out, FIFO

- Function variant: 223

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Autonomous

- Variant: No choice

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. First In First Out, FIFO

- Function variant: 224

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Sensor

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Waiting for PLC command:

- Receive from conveyor 1 or Receive from conveyor 2

- Function variant: 225

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: No choice

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. First In First Out, FIFO

- Function variant: 226

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Sensor

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Waiting for PLC command:

- Receive from conveyor 1 or Receive from conveyor 2

- Function variant: 312

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Only PLC

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Waiting for PLC command:

- Receive from conveyor 1 or Receive from conveyor 2

- Function variant: 313

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Only PLC

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Waiting for PLC command:

- Receive from conveyor 1 or Receive from conveyor 2

Merger 90, Left

- Function group: 10

- Function variant: 74

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Autonomous

- Variant: No choice

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. First In First Out, FIFO

- Function variant: 75

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Line control

- Variant: No choice

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Waiting for PLC command:

- Receive from conveyor 1 or Receive from conveyor 2

- Function variant: 76

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: No choice

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. First In First Out, FIFO

- Function variant: 77

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Line control

- Variant: No choice

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Waiting for PLC command:

- Receive from conveyor 1 or Receive from conveyor 2

- Function variant: 78

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: No choice

Motor is enabled when power is on. Alarm resets when reboot. First In First Out, FIFO

- Function variant: 227

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Autonomous

- Variant: No choice

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. First In First Out, FIFO

- Function variant: 228

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Sensor

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Waiting for PLC command:

- Receive from conveyor 1 or Receive from conveyor 2

- Function variant: 229

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Autonomous

- Variant: No choice

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. First In First Out, FIFO

- Function variant: 230

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Sensor

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Waiting for PLC command:

- Receive from conveyor 1 or Receive from conveyor 2

- Function variant: 314

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Only PLC

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Waiting for PLC command:

- Receive from conveyor 1 or Receive from conveyor 2

- Function variant: 315

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Only PLC

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Waiting for PLC command:

- Receive from conveyor 1 or Receive from conveyor 2

Combined Merger / Diverter parallel, Right

- Function group: 11

- Function variant: 79

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Line control

- Variant: No choice

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Waiting for PLC command:

- (Receive from conveyor 1 or Receive from conveyor 2) and (Release to conveyor 1 or Release to conveyor 2)

- Function variant: 80

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Line control

- Variant: No choice

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Waiting for PLC command:

- (Receive from conveyor 1 or Receive from conveyor 2) and (Release to conveyor 1 or Release to conveyor 2)

- Function variant: 81

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: No choice

Motor is enabled when power is on. Alarm resets when reboot. Pucks from conveyor 1 is returned on conveyor 2. Pucks from conveyor 2 is returned on conveyor 1.

- Function variant: 231

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Sensor

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Waiting for PLC command:

- (Receive from conveyor 1 or Receive from conveyor 2) and (Release to conveyor 1 or Release to conveyor 2)

- Function variant: 232

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Sensor

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Waiting for PLC command:

- (Receive from conveyor 1 or Receive from conveyor 2) and (Release to conveyor 1 or Release to conveyor 2)

- Function variant: 316

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Only PLC

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Waiting for PLC command:

- (Receive from conveyor 1 or Receive from conveyor 2) and (Release to conveyor 1 or Release to conveyor 2)

- Function variant: 317

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Only PLC

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Waiting for PLC command:

- (Receive from conveyor 1 or Receive from conveyor 2) and (Release to conveyor 1 or Release to conveyor 2)

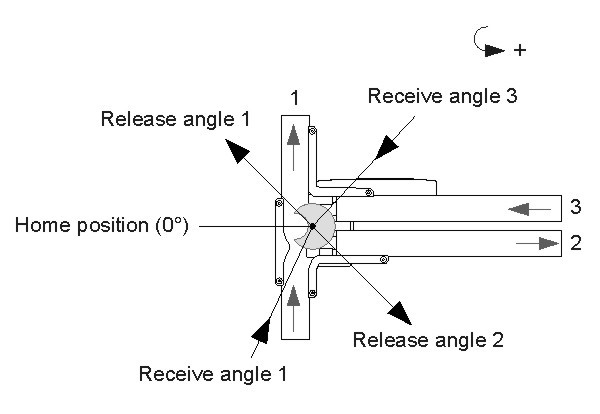

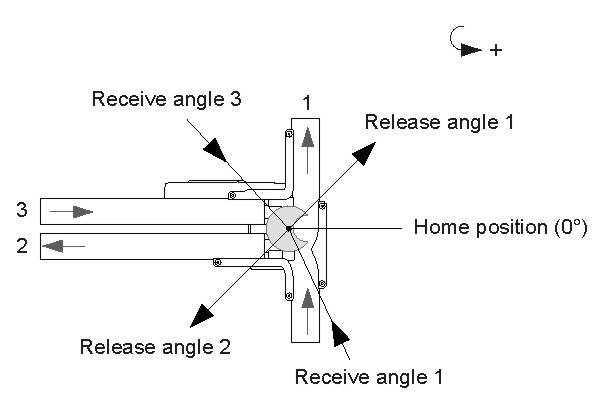

Combined Merger / Diverter 90, Right

- Function group: 12

- Function variant: 82

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Line control

- Variant: No choice

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Waiting for PLC command:

- (Receive from conveyor 1 or Receive from conveyor 3) and (Release to conveyor 1 or Release to conveyor 2)

- Function variant: 83

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Line control

- Variant: No choice

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Waiting for PLC command:

- (Receive from conveyor 1 or Receive from conveyor 3) and (Release to conveyor 1 or Release to conveyor 2)

- Function variant: 84

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: No choice

Motor is enabled when power is on. Alarm resets when reboot. Pucks from conveyor 1 is returned on conveyor 2. Pucks from conveyor 3 is returned on conveyor 1.

- Function variant: 233

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Sensor

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Waiting for PLC command:

- (Receive from conveyor 1 or Receive from conveyor 3) and (Release to conveyor 1 or Release to conveyor 2)

- Function variant: 234

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Sensor

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Waiting for PLC command:

- (Receive from conveyor 1 or Receive from conveyor 3) and (Release to conveyor 1 or Release to conveyor 2)

- Function variant: 318

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Only PLC

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Waiting for PLC command:

- (Receive from conveyor 1 or Receive from conveyor 3) and (Release to conveyor 1 or Release to conveyor 2)

- Function variant: 319

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Only PLC

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Waiting for PLC command:

- (Receive from conveyor 1 or Receive from conveyor 3) and (Release to conveyor 1 or Release to conveyor 2)

Combined Merger / Diverter parallel, Left

- Function group: 13

- Function variant: 85

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Line control

- Variant: No choice

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Waiting for PLC command:

- (Receive from conveyor 1 or Receive from conveyor 2) and (Release to conveyor 1 or Release to conveyor 2)

- Function variant: 86

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Line control

- Variant: No choice

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Waiting for PLC command:

- (Receive from conveyor 1 or Receive from conveyor 2) and (Release to conveyor 1 or Release to conveyor 2)

- Function variant: 87

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: No choice

Motor is enabled when power is on. Alarm resets when reboot. Pucks from conveyor 1 is returned on conveyor 2. Pucks from conveyor 2 is returned on conveyor 1.

- Function variant: 235

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Sensor

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Waiting for PLC command:

- (Receive from conveyor 1 or Receive from conveyor 2) and (Release to conveyor 1 or Release to conveyor 2)

- Function variant: 236

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Sensor

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Waiting for PLC command:

- (Receive from conveyor 1 or Receive from conveyor 2) and (Release to conveyor 1 or Release to conveyor 2)

- Function variant: 320

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Only PLC

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Waiting for PLC command:

- (Receive from conveyor 1 or Receive from conveyor 2) and (Release to conveyor 1 or Release to conveyor 2)

- Function variant: 321

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Only PLC

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Waiting for PLC command:

- (Receive from conveyor 1 or Receive from conveyor 2) and (Release to conveyor 1 or Release to conveyor 2)

Combined Merger / Diverter 90, Left

- Function group: 14

- Function variant: 88

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Line control

- Variant: No choice

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Waiting for PLC command:

- (Receive from conveyor 1 or Receive from conveyor 3) and (Release to conveyor 1 or Release to conveyor 2)

- Function variant: 89

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Line control

- Variant: No choice

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Waiting for PLC command:

- (Receive from conveyor 1 or Receive from conveyor 3) and (Release to conveyor 1 or Release to conveyor 2)

- Function variant: 90

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: No choice

Motor is enabled when power is on. Alarm resets when reboot. Pucks from conveyor 1 is returned on conveyor 2. Pucks from conveyor 3 is returned on conveyor 1.

- Function variant: 237

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Sensor

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Waiting for PLC command:

- (Receive from conveyor 1 or Receive from conveyor 3) and (Release to conveyor 1 or Release to conveyor 2)

- Function variant: 238

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Sensor

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Waiting for PLC command:

- (Receive from conveyor 1 or Receive from conveyor 3) and (Release to conveyor 1 or Release to conveyor 2)

- Function variant: 322

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Only PLC

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Waiting for PLC command:

- (Receive from conveyor 1 or Receive from conveyor 3) and (Release to conveyor 1 or Release to conveyor 2)

- Function variant: 323

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Only PLC

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Waiting for PLC command:

- (Receive from conveyor 1 or Receive from conveyor 3) and (Release to conveyor 1 or Release to conveyor 2)

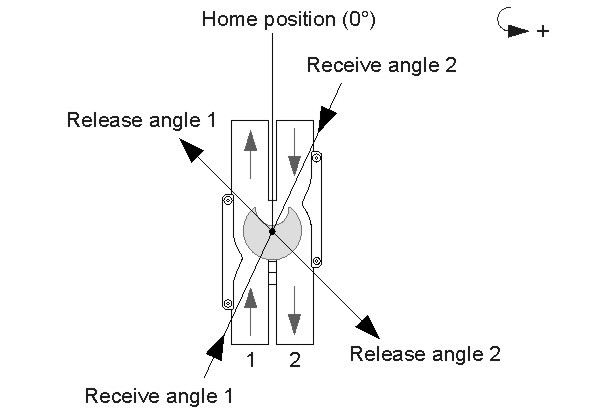

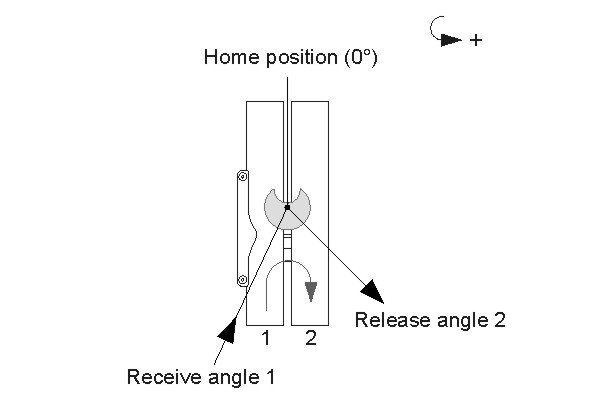

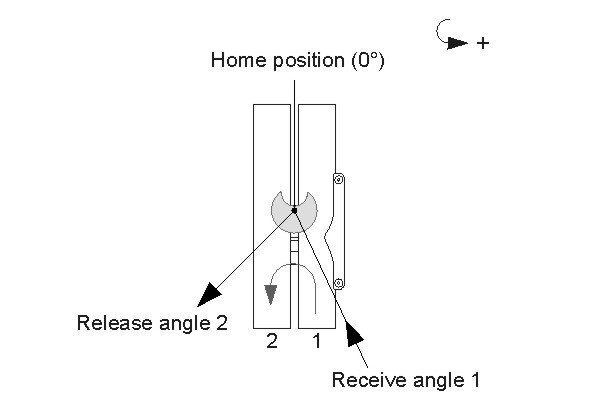

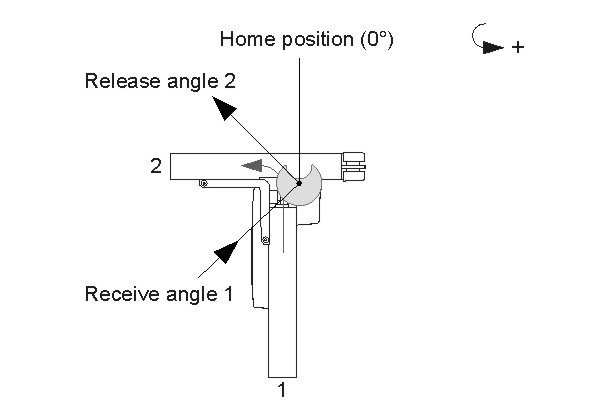

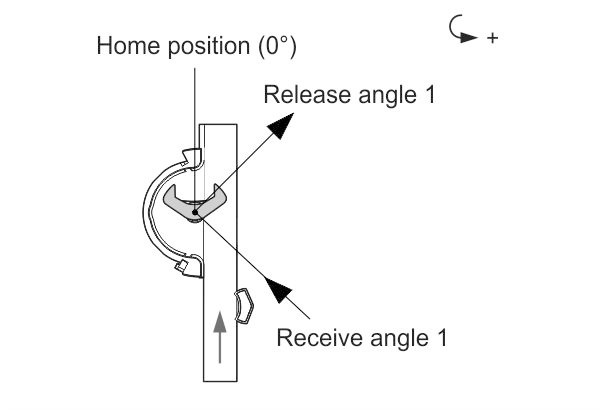

Transfer 180, Right

- Function group: 15

- Function variant: 91

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Guide disc starts at Release angle 2. Waiting for PLC command

- Receive from conveyor 1

Sensor DI1 is triggering movement to Release angle 2

- Function variant: 92

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Guide disc starts at Release angle 2. Waiting for PLC command

- Receive from conveyor 1

Sensor DI1 is triggering movement to Release angle 2

- Function variant: 93

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: Normally open

Motor is enabled when power is on. Alarm resets when reboot. Guide disc starts at Release angle 2. Guide disc will automatically move to Receive angle 1 if not Interlock is active. Sensor DI1 is triggering movement to Release angle 2

- Function variant: 239

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Guide disc starts at Release angle 2. Waiting for PLC command

- Receive from conveyor 1

Sensor DI1 is triggering movement to Release angle 2

- Function variant: 240

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Guide disc starts at Release angle 2. Waiting for PLC command

- Receive from conveyor 1

Sensor DI1 is triggering movement to Release angle 2

- Function variant: 324

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed, only PLC

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Guide disc starts at Release angle 2. Waiting for PLC command

- Receive from conveyor 1

PLC is triggering movement to Release angle 2

- Function variant: 325

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed, only PLC

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Guide disc starts at Release angle 2. Waiting for PLC command

- Receive from conveyor 1

PLC is triggering movement to Release angle 2

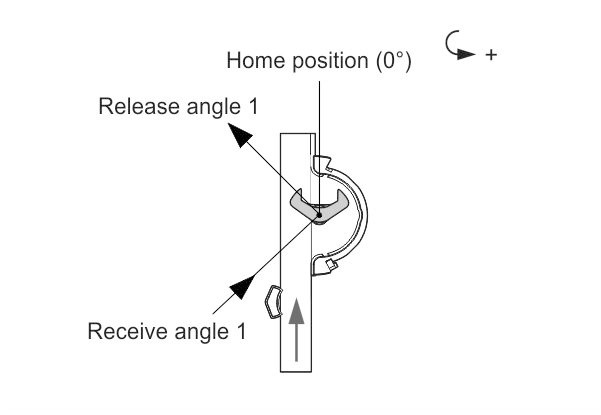

Transfer 90, Right

- Function group: 16

- Function variant: 94

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Guide disc starts at Release angle 2. Waiting for PLC command

- Receive from conveyor 1

Sensor DI1 is triggering movement to Release angle 2

- Function variant: 95

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Guide disc starts at Release angle 2. Waiting for PLC command

- Receive from conveyor 1

Sensor DI1 is triggering movement to Release angle 2

- Function variant: 96

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: Normally open

Motor is enabled when power is on. Alarm resets when reboot. Guide disc starts at Release angle 2. Guide disc will automatically move to Receive angle 1 if not Interlock is active. Sensor DI1 is triggering movement to Release angle 2

- Function variant: 241

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Guide disc starts at Release angle 2. Waiting for PLC command

- Receive from conveyor 1

Sensor DI1 is triggering movement to Release angle 2

- Function variant: 242

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Guide disc starts at Release angle 2. Waiting for PLC command

- Receive from conveyor 1

Sensor DI1 is triggering movement to Release angle 2

- Function variant: 326

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed, only PLC

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Guide disc starts at Release angle 2. Waiting for PLC command

- Receive from conveyor 1

PLC is triggering movement to Release angle 2

- Function variant: 327

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed, only PLC

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Guide disc starts at Release angle 2. Waiting for PLC command

- Receive from conveyor 1

PLC is triggering movement to Release angle 2

Transfer 180, Left

- Function group: 17

- Function variant: 97

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Guide disc starts at Release angle 2. Waiting for PLC command

- Receive from conveyor 1

Sensor DI1 is triggering movement to Release angle 2

- Function variant: 98

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Guide disc starts at Release angle 2. Waiting for PLC command

- Receive from conveyor 1

Sensor DI1 is triggering movement to Release angle 2

- Function variant: 99

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: Normally open

Motor is enabled when power is on. Alarm resets when reboot. Guide disc starts at Release angle 2. Guide disc will automatically move to Receive angle 1 if not Interlock is active. Sensor DI1 is triggering movement to Release angle 2

- Function variant: 243

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Guide disc starts at Release angle 2. Waiting for PLC command

- Receive from conveyor 1

Sensor DI1 is triggering movement to Release angle 2

- Function variant: 244

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Guide disc starts at Release angle 2. Waiting for PLC command

- Receive from conveyor 1

Sensor DI1 is triggering movement to Release angle 2

- Function variant: 328

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed, only PLC

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Guide disc starts at Release angle 2. Waiting for PLC command

- Receive from conveyor 1

PLC is triggering movement to Release angle 2

- Function variant: 329

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed, only PLC

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Guide disc starts at Release angle 2. Waiting for PLC command

- Receive from conveyor 1

PLC is triggering movement to Release angle 2

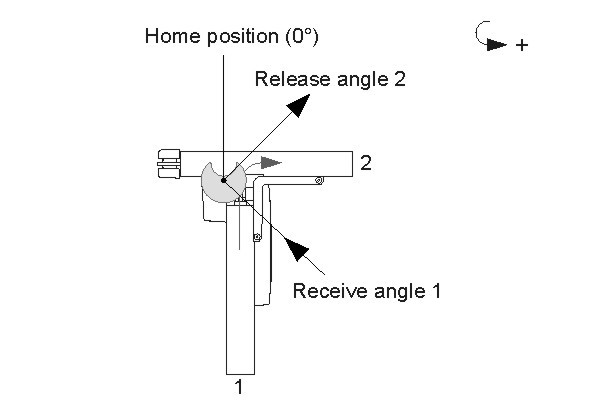

Transfer 90, Left

- Function group: 18

- Function variant: 100

- A-Bus protocol: CANopen

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via CANopen. Alarm resets on reset bit via CANopen. Guide disc starts at Release angle 2. Waiting for PLC command

- Receive from conveyor 1

Sensor DI1 is triggering movement to Release angle 2

- Function variant: 101

- A-Bus protocol: DeviceNet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via DeviceNet. Alarm resets on reset bit via DeviceNet. Guide disc starts at Release angle 2. Waiting for PLC command

- Receive from conveyor 1

Sensor DI1 is triggering movement to Release angle 2

- Function variant: 102

- A-Bus protocol: None

- Enable-Reset: Autonomous

- Control: Autonomous

- Variant: Normally open

Motor is enabled when power is on. Alarm resets when reboot. Guide disc starts at Release angle 2. Guide disc will automatically move to Receive angle 1 if not Interlock is active. Sensor DI1 is triggering movement to Release angle 2

- Function variant: 245

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Guide disc starts at Release angle 2. Waiting for PLC command

- Receive from conveyor 1

Sensor DI1 is triggering movement to Release angle 2

- Function variant: 246

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Guide disc starts at Release angle 2. Waiting for PLC command

- Receive from conveyor 1

Sensor DI1 is triggering movement to Release angle 2

- Function variant: 330

- A-Bus protocol: Ethernet/IP

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed, only PLC

Motor is enabled via Ethernet/IP. Alarm resets on reset bit via Ethernet/IP. Guide disc starts at Release angle 2. Waiting for PLC command

- Receive from conveyor 1

PLC is triggering movement to Release angle 2

- Function variant: 331

- A-Bus protocol: Profinet

- Enable-Reset: Line control

- Control: Line control

- Variant: Normally closed, only PLC

Motor is enabled via Profinet. Alarm resets on reset bit via Profinet. Guide disc starts at Release angle 2. Waiting for PLC command

- Receive from conveyor 1

PLC is triggering movement to Release angle 2

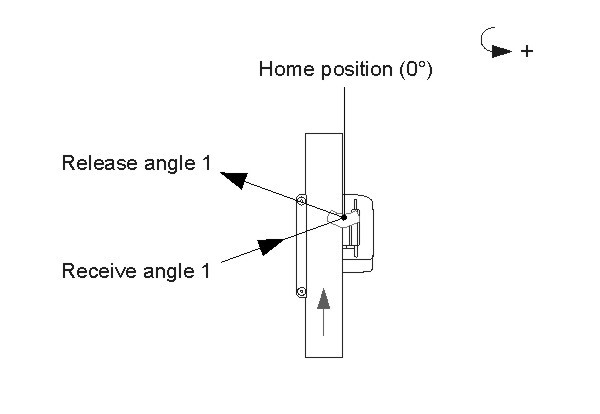

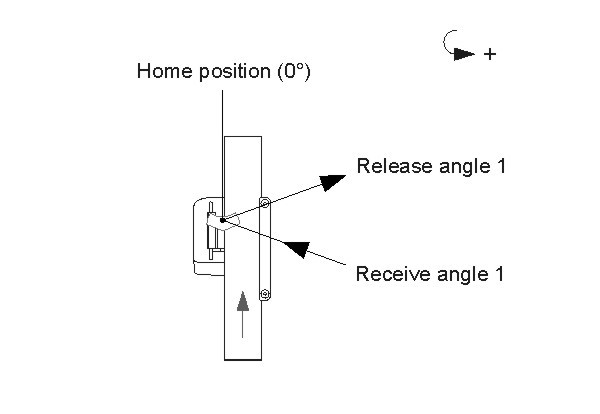

Stop unit, Right

- Function group: 19

- Function variant: 139