Background

The X45e units can be controlled either with or without a field bus network. If no field bus are present it is referred to as stand-alone or autonomous mode. The stand-alone mode is most useful in simple application and especially for conveyor drives. This article focuses only on the control of conveyor drives. It exists in two different sub modes, Sensor mode or Limit switch mode.

For deeper information please check the following manuals:

- User documentation – Electrical System (X45e)

- User documentation – Parameter Setting Tool

Prerequisites

Hardware

- PC (Windows 7 or later)

- X45e conveyor unit (with power cables)

- Parameter Setting Tool cable (X45e) or mini USB cable depending on hardware version

Software

- X45e – Parameter Setting Tool

Software version

Make sure the unit has the latest software versions installed. Look at MyFlexLink under the Download Area for information about the latest release. This article was written when the FEG version 59 was the latest version. The PST version used is 3.0.12.

Wizard

To set the proper parameter setting to the conveyor unit the wizard is a good help. This is started with the command Change Node.

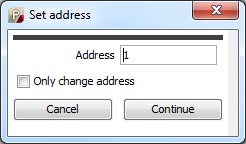

The first step of the wizard is the setting of the address of the node. This node address can be set to any required value (max 126). If the unit should be a part of a system with one configuration file it has to have a unique address even though it is not connected to a field bus.

The next window in the wizard decides which (physical) type the unit should be set to. For a conveyor unit it has only two alternatives, the left or the right version, and the User Defined version. The later option is not automatically setting the other parameters but leaves this to the user. The right and the left version only differs by the sign of the speed setpoint. This setpoint can be changed later from the settings window.

The Network settings window should in the stand-alone case be set to None.

The last popup window in the wizard is the control settings window. The first two choices (Enable-Reset and Control) could not be set to anything else than Autonomous, because no network was selected in the previous window.

The Variant parameter could be set in two different modes, Sensor or Limit switch mode. Both these variants has two speed setpoints but they differ in how they are used.

The Sensor mode is basically controlling the speed setpoint with one digital input (DI3). If this digital input is activated the speed setpoint 2 is used as the speed on the conveyor. If DI3 isn’t activated the speed setpoint 1 is used.

The Limit switch mode is controlling the speed setpoint by using two digital inputs (DI3 and DI4). The conveyor is running with speed setpoint 1 until DI3 is activated. Then the conveyor is stopped a number of milliseconds. This time delay is specified in the parameter Limit switch wait. After this delay the conveyor is started again but this time with the speed setpoint 2. It is running with this speed until DI4 is activated. Then the conveyor is stopped once again in the same delay time as described above. Then the conveyor is starting again with speed setpoint 1 and the sequence is repeated all over again.

The Interlock parameter controls (by the status of digital input DI4) if the unit should be temporary stopped even though the enable signal is set. In stand-alone mode the enable bit is always on so the Interlock signal is the only way to stop the drive. If this parameter is set to None the interlock function is not active. If it is set to Normally open then DI4 must be unactivated in order to get the conveyor to run. On the contrary Normally closed means DI4 has to be activated to run the conveyor.

After the wizard is completed the unit is updated with these settings (if working in Direct mode). Also all of the parameters in the settings windows are updated to the unit. If some of these parameters should be changed this could be done via the Parameter Setting Tool.

There is also a possibility to adjust the speeds setpoints using the digital input signals. The digital input 1 (DI1) is increasing the speed setpoint parameter. It increases the values with 1 rpm/s the first two seconds. After this it increases the value with 10 rpm/s. The digital input 2 (DI2) is decreasing the speed setpoint parameter with the same timer function. This fine tuning procedure is adjusting the speed setpoint that currently is chosen.