Background

The X45e units are primarily design for the platform X45/X45e/X45H. Still they can be used for a lot of different applications. The units could also be used as a generic motion control for other purposes. This article explains one of these option, the positioning mode.

For deeper information please check the following manuals:

- User documentation – Electrical System (X45e)

- User documentation – Parameter Setting Tool

Also check separate Knowledge Base articles on CANopen and DeviceNet communication.

Prerequisites

Hardware

- PC (Windows 7 or later)

- X45e function unit (with power cables)

- Parameter Setting Tool cable (X45e) or mini USB cable depending on hardware version

Software

- X45e – Parameter Setting Tool

Parameter Setting Tool

The first step is to prepare the X45e function unit for the positioning mode.

Software version

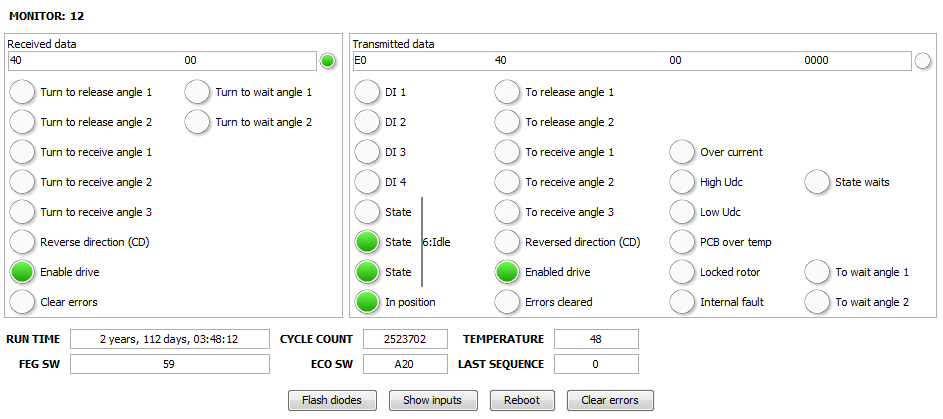

The FEG_SW in the unit should be of version 59 or later. The ECO_SW should be of version 20 or later. The existing version numbers can be checked with the Parameter Setting Tool software from the Monitor page (Tools menu).

If they should be upgraded this is done from the menu Tools -> Activities -> Firmware update. The latest software versions can be downloaded from MyFlexLink under the Download Area.

Wizard (Change Node)

When the unit is upgraded to correct software versions it could be set to a Position mode using the Change Node command under the Edit menu.

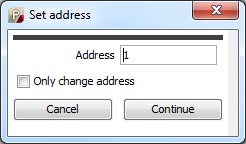

This triggers a wizard to be started. As the first step of this wizard the address of the unit could be changed.

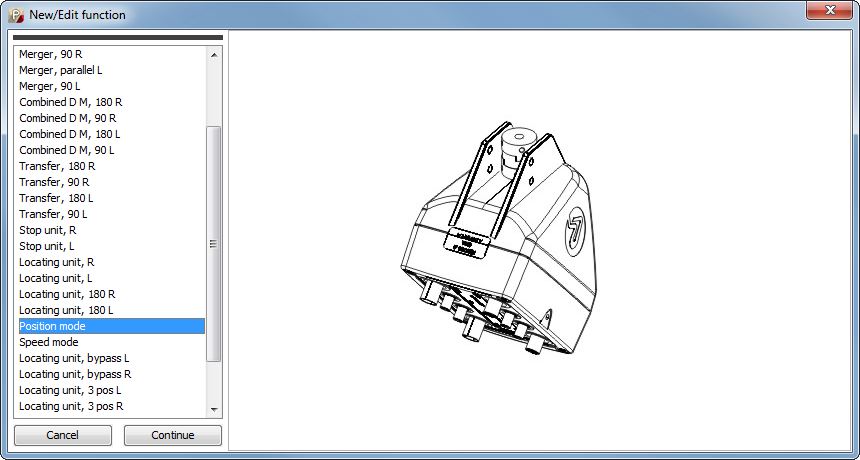

After the node address the function type has to be specified. In this case it should be set to Position mode. This is only valid for function motors.

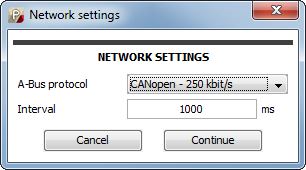

The next step is to decide how the unit should interact with a line controller. For a Position mode type it is only possible to choose CANopen or DeviceNet.

The last step of the wizard is the control settings. The only value possible to change is the Interlock parameter which controls if the unit should be paused on a sensor input (DI4). This isn’t very useful in the case and should be set to None.

When the wizard is finished all parameters are automatically written to the function unit.

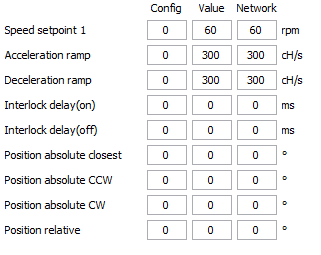

Only valid setting are shown in the settings window (below).

The first three parameters are set to default values. These can easily be changed from here if they shouldn’t be changed dynamically from the line controller.

The four last parameters are position mode related but they are not activated from the Parameter Setting Tool. These should be read and written from the line controller instead (see next chapter).

Calibration

If the zero position is wrong this could be changed with the Calibration command from the Tools menu under Activites.

Interlock

If the interlock mode is set to either 1 or 2 the digital input DI4 can stop the movement. This could be used to run to an end position.

Line control communication

The position control is a mode for the function motors only. It requires DeviceNet, CANopen, Ethernet/IP or Profinet to work (depending on hardware version). The basic idea is to get more freedom on how to control the axis to different positions (or actually angles). The line control communication can be divided into two parts. The first part is the time critical communication send repeatedly. Then there is the communication dealing with settings. This is only read or written at request. The technical terms on these communication parts differs depending on network protocol.

PDO / Cyclic communication

This is a part of the PDO communication in CANopen or the cyclic communication in DeviceNet, Ethernet/IP or Profinet. All units has to receive an Enable bit from the line controller. Also the reset bit can be useful to acknowledge existing alarms on the X45e unit. As a feedback there are several useful bits. Especially the alarm bits and the InPosition bit are important. See the user manual for more details. All these data can be monitored via the Parameter setting Tool, see the picture above showing software versions.

SDO / Acyclic communication

This is a part of the SDO communication in CANopen or the acyclic communication in DeviceNet, Ethernet/IP or Profinet. All these parameter are triggered from the line controller.

Position Absolute Closest

CANopen: Index 4000 (hex); SDO SubIndex 56 (dec)

DeviceNet: Class 70 (hex); Instance 56 (dec)

Ethernet/IP: Class 0F (hex); Attribute 1; Instance 56 (dec)

Profinet: API 0; Slot 1; Sub slot 1; Index 71 (dec)

This is a command parameter where the new position [0 ; 360°] is sent from the line controller to the function unit. The function unit will evaluate the current position and calculate the closest direction to reach its new destination.

Position Absolute Counter Clockwise

CANopen: Index 4000 (hex); SDO SubIndex 57 (dec)

DeviceNet: Class 70 (hex); Instance 57 (dec)

Ethernet/IP: Class 0F (hex); Attribute 1; Instance 57 (dec)

Profinet: API 0; Slot 1; Sub slot 1; Index 72 (dec)

This is a command parameter where the new position [0 ; 360°] is sent from the line controller to the function unit. The function unit will always move counter clockwise to reach its new destination.

Position Absolute Clockwise

CANopen: Index 4000 (hex); SDO SubIndex 58 (dec)

DeviceNet: Class 70 (hex); Instance 58 (dec)

Ethernet/IP: Class 0F (hex); Attribute 1; Instance 58 (dec)

Profinet: API 0; Slot 1; Sub slot 1; Index 73 (dec)

This is a command parameter where the new position [0 ; 360°] is sent from the line controller to the function unit. The function unit will always move clockwise to reach its new destination.

Position Relative

CANopen: Index 4000 (hex); SDO SubIndex 59 (dec)

DeviceNet: Class 70 (hex); Instance 59 (dec)

Ethernet/IP: Class 0F (hex); Attribute 1; Instance 59 (dec)

Profinet: API 0; Slot 1; Sub slot 1; Index 74 (dec)

This is a command parameter where the new distance [-32768 ; 32767°] is sent from the line controller to the function unit. The function unit can move either direction all depending on the sign of the relative distance.

Position Actual CCW

CANopen: Index 4000 (hex); SDO SubIndex 60 (dec)

DeviceNet: Class 70 (hex); Instance 60 (dec)

Ethernet/IP: Class 0F (hex); Attribute 1; Instance 60 (dec)

Profinet: API 0; Slot 1; Sub slot 1; Index 18 (dec)

This is a feedback parameter where the actual postion [0 ; 360°] is sent from the function unit to the line controller.

Position Actual CW

CANopen: Index 4000 (hex); SDO SubIndex 61 (dec)

DeviceNet: Class 70 (hex); Instance 61 (dec)

Ethernet/IP: Class 0F (hex); Attribute 1; Instance 61 (dec)

Profinet: API 0; Slot 1; Sub slot 1; Index 19 (dec)

This is a feedback parameter where the actual postion [0 ; 360°] is sent from the function unit to the line controller.